“When a family member gives you a second chance at life and it fails, it almost feels like it’s your fault. It’s not, but it does,” said Sarah Hyland, an American actress after the kidney she received from her father was rejected by her body. Sarah has now received a kidney from her brother which keeps her going.

Years of advances and developments in medicine and clinical research have enabled us to treat or manage diseases that were once deadly. However, there’s a lot more to be achieved. As of today, millions of people still suffer from debilitating conditions, and those conditions cannot be solved with the current tools.

Here is some data – 10% of the population worldwide is affected by chronic kidney disease (CKD), and millions die each year because they do not have access to affordable treatment. An estimated 1.5 billion persons have (Chronic Liver Disease) CLD worldwide. Globally, there are approximately 1500 cases of acid attacks on women. These attacks leave them with a lifetime of challenges to overcome.

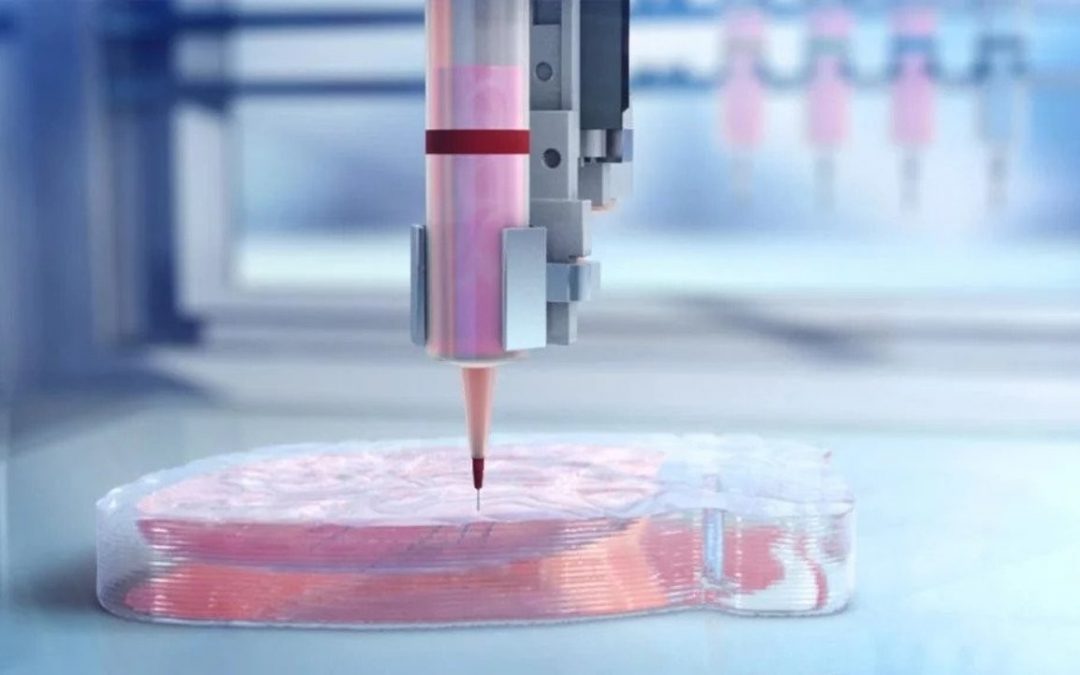

And the list goes on and on with patients suffering from a wide range of conditions. With this in mind, there is one such tool that might be able to help them by treating their conditions. 3D Bioprinting is a modern marvel which allows scientists to “print” an actual organ from scratch! Imagine a situation where a person is diagnosed with liver failure and is in dire need of a transplant but there’s a long waitlist. In such cases, 3D bioprinting can be employed to “print” a liver using cells from the patient.

3D bioprinting works similarly to a 3D printer. To make the desired product, a 3D printer ejects molten thermoplastics like PLA and ABS in a specific pattern. On the other hand, unlike a 3D printer, a 3D bioprinter uses bio-ink, which is a combination of biopolymers and tissue cells.

“Human body is built-up by a combination of numerous tissue types. Tissues in the human body are made up of cells. But these cells are bound to each other with an extracellular matrix. These matrices are polymeric structures, for e.g. fibronectin and collagen. During the development of 3D culture, the same human physiology is mimicked by using these types of biopolymers that are compatible with mammalian cells.” – Junaid Parkar, Senior Research Fellow, NRG.

A 3D bioprinter can capture all the minute physical features of an organ and thus has great potential in tissue engineering and regenerative medicine. The market for 3D bioprinting is growing every year as technology advances. In India, Avay Biosciences is a producer of 3D bioprinters. The current stage of 3D bioprinting is at developing standardized bioinks. To solve this problem, researchers at Nanomedicine Research Group (NRG) developed guar-gum-gelatin bioink, which is compatible with mammalian cells.

Explaining the scope of 3D bioprinting, Junaid Parkar who works on skin bioprinting said “Scope is determined by the potential benefits. Wherever we find the benefits of a material’s application, is where the scope of that material or technology lies. So, 3D culture mainly would prove to be beneficial for artificial tissue or organ development for uses like replacing the damaged ones in a human body and for the initial studies of the medical students, thereby reducing the load on the cadavers and eventually reducing the ethical burden on the society.”

“3D culture mainly would prove to be beneficial towards artificial tissue or organ development for uses like replacing the damaged ones in a human body” – Junaid Parkar.

I contacted Dr. Prajakta Dandekar, an eminent scientist at NRG who is a Principal Investigator in the field of 3D Cell Culture, to learn more about the potential of 3D bioprinting. She explained “3D bioprinting uses cells and biocompatible materials also known as bioinks, to print living structures in a layer-by-layer manner, which may mimic the behaviour of natural living systems. While common in the areas of bioengineering, tissue engineering, and material science, these structures are being increasingly employed for pharmaceutical development and drug validation and in the future may be used for medical applications like 3D grafts, grafts, implants, biomedical devices, and even whole organs, all of which are active in research.” Artificial organs made using 3D bioprinting also have a huge advantage in the pharmaceutical industry as they will offer a great platform to test and validate new drugs before coming to the market.

On asking about the difficulties of working in a field that is at a naive stage of development, Junaid said, “Due to the lack of expertise in this field many issues that we face are not even reported in any public domain. Trial and error along with a continual track of the observations are what helps to tackle such unknown problems.”

It is going to be a momentous couple of decades for the entire world, thanks to technological leaps like 3D bioprinting and many more which are going to change humans’ lives forever.

Written by: Parth Choudhari (Science Communicator, Nanomedicine Research Group)